Woodworking jointers are essential tools for anyone looking to get serious about their projects. They help create flat surfaces on wood, making it easier to work with and ensuring that your pieces fit together perfectly. If you want to build furniture or do woodworking as a hobby, a jointer will quickly become your best friend.

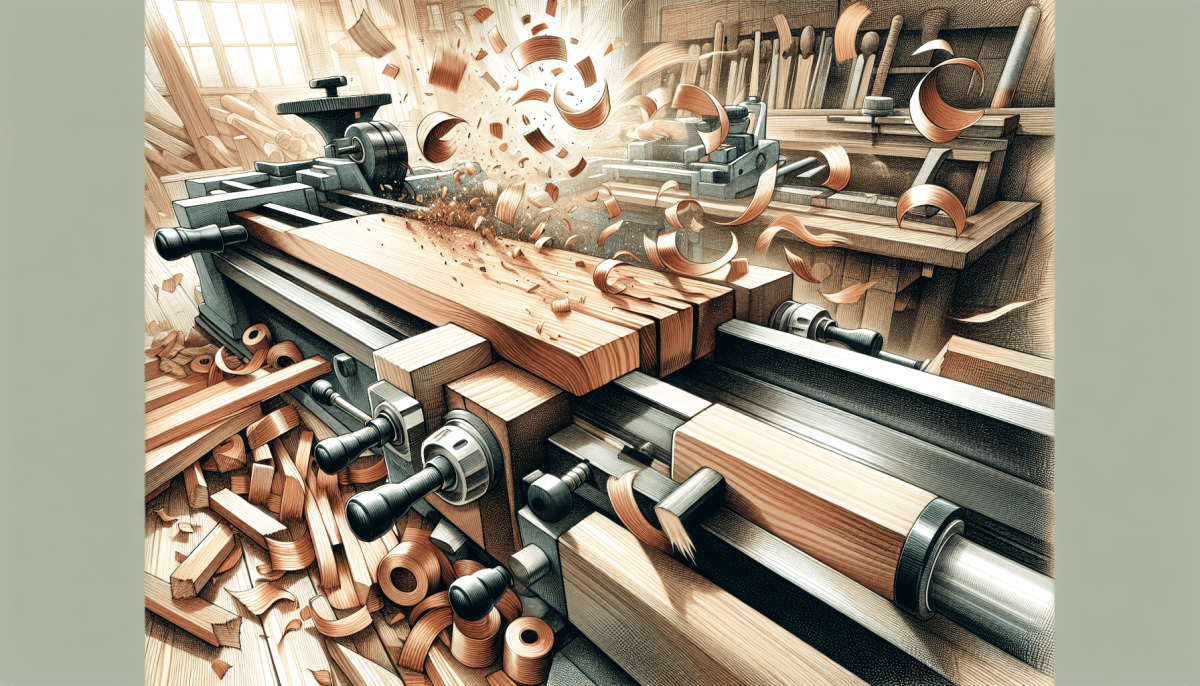

The main function of a jointer is to flatten rough lumber. When you bring home a piece of wood, it often has twists, cupping, or warping. A jointer removes these imperfections, allowing you to start with a clean slate. It works by passing the wood over a set of sharp knives mounted on a rotating cutter head. This action shaves off thin layers of wood to create a flat surface.

There are different types of jointers, but most woodworkers stick to two main kinds: benchtop and floor-standing models. Benchtop jointers are smaller, portable, and ideal for folks with limited workspace. They’re a great choice if you’re just starting out or often work on smaller projects. On the other hand, floor-standing models are larger and can handle bigger pieces of lumber. They're more stable and can offer better precision, which is essential for larger woodworking jobs.

When choosing a jointer, think about the size of your projects and available workspace. Look for features like the width of the cutting table and the horsepower of the motor. If you plan to work with wider boards, a jointer with a larger bed is a must. Don’t forget to consider ease of adjustment—having smooth controls for adjusting the depth of cut will save you a lot of frustration.

Choosing the Right Jointer for You

Picking the right jointer can feel a bit overwhelming, but it doesn’t have to be. First, think about your workspace. Do you have a big garage or a small shed? Jointers come in different sizes. If you’re tight on space, a benchtop model might be your best bet. They’re compact, portable, and get the job done without hogging your setup.

Next, consider the type of wood you’ll be working with. If you’re planning to work with larger boards, look for a jointer with a wider cutting bed. Wider beds help with stability and make it easier to flatten those big pieces. You don’t want to end up wrestling with your wood because your jointer is too small!

Pay attention to the power of the motor, too. A stronger motor means smoother cuts, especially when you’re dealing with tougher woods. You’ll want something that can handle your projects without struggling. Check the cutting width and depth settings as well, as they determine how much material you can take off in one pass.

Don’t forget about features that make your life easier. Look for jointers with good adjustments, like easy-to-read scales and smooth controls. Some jointers come with built-in dust collection features, which is a major plus for keeping your workspace clean. It’s all about finding the right balance between power, performance, and convenience for your needs.

Tips for Using Your Jointer

Using a jointer can feel a bit tricky at first, but once you get the hang of it, you'll wonder how you ever worked without one. Here are some tips to help you navigate your jointer with confidence.

First off, always make sure your boards are clean and free of any debris. Dust and dirt can mess with the precision of your cuts. A quick wipe-down can save you a lot of hassle later on. When you’re ready to start, feed the wood in straight and don’t force it through. Let the machine do the work; just guide it along.

Adjust your jointer's knives properly. Dull blades can ruin your work and make your life a lot harder than it needs to be. Keep them sharp and aligned; this will give you smoother and more accurate cuts. If you're getting tear-out or rough patches, it’s time for a tune-up on those knives!

Don’t forget to check the infeed and outfeed tables. They need to be level with your jointer's knives. If they’re not, you could end up with snipe on your boards, which is super frustrating. A little fine-tuning goes a long way in preventing mistakes.

Lastly, practice makes perfect. If you're new to using a jointer, start with some scrap wood. Get a feel for how it works and understand the way it affects your pieces. Before you know it, you’ll be flattening and squaring edges like a pro!

Common Mistakes and How to Avoid Them

When you're getting into woodworking jointers, it’s easy to make some common mistakes. These slip-ups can lead to frustration or lousy results, but don’t worry! I'm here to help you sidestep those issues.

One big mistake is not understanding the grain direction of your wood. If you run your boards through the jointer the wrong way, you might end up with tear-out. Always take a moment to check the grain. Going with the flow can save you a ton of headache.

Another issue folks run into is improper setup of their jointer. If your outfeed table isn't aligned properly, it can cause your boards to be uneven. A quick check with a straight edge can save a lot of trouble. Make sure everything is squared up before you start. That way, you get nice flat edges every time.

Don't forget about safety! A lot of new woodworkers neglect the importance of using push sticks or safety glasses. Protecting yourself should always be a priority. A small safety measure can prevent big accidents.

Finally, some people rush through the process. Patience is key in woodworking. Take your time to feed the wood through at a steady pace. This will not only give you better results but also make your projects more enjoyable. Happy woodworking!